Your cart is currently empty!

Why destratify?

[vc_row el_class=”realisations”][vc_column el_class=”blog”][rs_header_title title_tag=”h1″ title=”What is destratification? And what’s it good for?” content_tag=”h2″ align=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_infobox title=”Le destratificateur un moyen économique important dans votre consommation de chauffage”][/vc_infobox][vc_column_text]Air destratifiers are increasingly used in industry, as they can save up to 30% on heating costs, and also provide comfort in the heated room by homogenizing the air with fan blades that ensure a good mixing ratio.

It’s also an environmentally-friendly way of dealing with energy loss. Given the rising cost of electricity, this installation quickly pays for itself. The CEE bonus is available for industrial destratifiers. We’d like to introduce you to this industrial destratifier, a device that is not well known to the general public, but which is becoming increasingly popular with industrialists.

What is a destratifier?

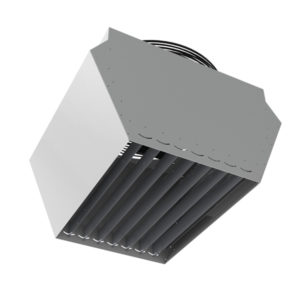

An air destratifier is a ventilation device used to save energy and keep heat down. The air destratifier is very useful when the ceiling height is high. (ceiling greater than or at least equal to 2m50). The destratifier achieves optimum mixing ratios in a forced-air heating system. This equipment consists of a heliocoil fan with blowing grilles and adjustable vanes (small blades). This fan is equipped with an isothermal sensor and a built-in, hard-wired thermostat that regulates speed to ensure optimum air circulation.[/vc_column_text][vc_row_inner content_placement=”middle”][vc_column_inner width=”1/2″][vc_single_image image=”9348″ alignment=”right”][/vc_column_inner][vc_column_inner width=”1/2″][vc_single_image image=”9420″][/vc_column_inner][/vc_row_inner][vc_column_text]

2 examples of destratifiers

[/vc_column_text][vc_column_text]

What is the function of an air destratifier?

The destratifier optimizes energy consumption by reducing it. Not to be confused with a simple fan. This system is mainly used in industrial environments, especially in winter.

What is the process?

Take, for example, a large, heated room, where the air is superimposed in different layers according to its temperature. Warm air is lighter than cold air, so it is trapped high up, exchanging its calories with the ceiling. Temperature differences can reach 1°C per metre in height, and 1.5°C for ceilings over 4 m.

Take, for example, a 10m-high industrial room heated to 15°C. You can have hot air at 25°C under the ceiling!

The destratifiers, located under the ceiling and evenly distributed throughout the room, are activated as soon as the warm air rises below the roof, and continuously stir up the warm air to force it down towards the ground. This is how we save money by recovering warm air that would otherwise be lost.

Destratifiers are therefore highly useful and recommended for large buildings, workshops, hangars, structures such as supermarkets, sacred buildings, gymnasiums, refectories, halls, industrial warehouses, etc.

The destratifier enables us to respond to an environmental policy that will be increasingly in demand from manufacturers. Not only by recovering energy losses, but also by reducing CO2 emissions.

There are two types of industrial destratifiers:

- Destratifiers with an electro-mechanical thermostat, automatically set to a given setpoint. For example, if the room set point is 12°C and the destratifier is located 6m above the floor, it is advisable to set the thermostat at around 16°C.

- Destratifiers with PT-100 electronic thermostats, found on the entire Flowair range. Their setpoint is adjusted by the T-box. This solution is much slimmer and more adjustable.

Installation of air destratifiers :

They are usually suspended by cables at about 2/3 of their height. To install them, we hire a cherry picker. Installation is usually permanent.

What type of destratifier should you choose for industry?

Fans for professional or industrial use are more expensive than those for private use. In fact, the destratification system is different. It’s not just a fan with a slow rotation.

Industrial destratifiers have a higher air flow rate, and the direction of air flow is controlled by adjustable vanes. Air flow is expressed in m3/h.

We then calculate the brewing rate required. It needs to be around 3 to perform well. To calculate this, divide the air flow rate by the volume of the room.

A thermostat and speed regulator are also recommended, if not necessary. For large volumes, we strongly recommend the TBOX remote control (intelligent home automation), which enables precise adjustment and thus optimization of energy management.

Consult polypoles to submit your project. Our design office and technical sales staff will respond precisely to your needs.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]We have installed numerous destratifiers. In these cases, the aim is to reduce heating costs. Opinions and feedback have been positive about both our installations and our products. Our technicians are true professionals who know their stuff.

Here are a few examples.

[/vc_column_text][vc_gallery type=”image_grid” images=”18097,18094,18095″ img_size=”400×250″][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Our destratifiers

[/vc_column_text]

[/vc_column][/vc_row]